3D View

The SSI Aeration Fine Bubble Diffuser is known around the world for its innovative design, reliable performance and precision manufacture. Our world wide service network supports our distributors and customers 24-7.

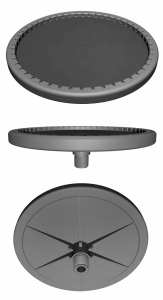

FINE BUBBLE DISC DIFFUSER

SSI Aeration’s Fine Bubble Disc Diffuser combines engineering excellence, superior component quality, and a technically advanced product design. Proven highly durable and efficient in thousands of municipal and industrial installations around the world, these advanced systems have reliability built into every stage of performance.

WHAT MAKES SSI AERATION’S DISC DIFFUSER A WORLDWIDE CHOICE?

- Molded EPDM membranes have tight wall thickness tolerances, a long and strong track record, and exhibit even air distribution and minimal shrinkage over time

- Patented PTFE membranes prolong efficiency, reduce plasticizer extraction, prevent membrane hardening, and limit dynamic changes, thereby reducing whole life costs

- Complete product line: 9” and 12” disc diffuser – create the system that fits your needs and budget

- Piping system integrity – thicker wall pipe and double anchors for fewer breakages

- SSI PODs connection is factory assembled to lower on-site labor costs, with shortest tank down time

- Grommet connection is easy to ship, move, and install on site. Affordable, tried and tested over 15 years

- Quick connect saddle allows installation with just a quarter turn of the diffuser and features an integral seal to ensure a leak-free connection. Allows membrane removal without disconnecting diffuser from the pipe.

- Comprehensive design service and after sales support – our full drafting department works with you through design and calculation to simulation and installation.

RELIABALL DIFFUSERS

The SSI Coarse Bubble Diffuser System is called ReliaBall™ for a reason. It combines engineering excellence, superior component quality, and a technically advanced product design. Proven highly durable and efficient in thousands of municipal and industrial installations around the world, SSI Aeration’s ReliaBall™ is a name to trust.

SSI ReliaBall™ Coarse Bubble Diffuser Unique System Strengths

- Intelligently designed to prevent clogging by automatically closing and sealing when air is turned off

- ReliaBall™ will not be clogged by rags in the tank

- The SSI ReliaBall™ headloss is approximately 10″ WG / 25 mbar when operated at 4 SCFM / 7 Sm3-hr (Operating Range: 0 to 10 scfm / 0-17 Sm3-hr)

- Piping system integrity – thicker wall pipe and double anchors for fewer breakages

- Grommet connection is easy to ship, move, and install on site – it’s affordable, tried and tested over 15 years

- Comprehensive design service and after sales support – our full drafting department works with you through design and calculation to simulation and installation

AFC CAP DIFFUSERS

Durable choice for aerobic digesters and equalization tanks

- SSI Aeration’s AFC Cap Diffusers are ideal where high rate oxygen transfer efficiency is not required

- Manufactured from black Acrylic plastic containing UV protection and membranes made from the same EPDM compound used in SSI fine bubble diffusers

- SSI AFC Cap diffusers have a ¾” MNPT thread

Design Flow: 3-6 SCFM (7-10 Nm3/hr)

Flow Range: 0-10 SCFM (0-17 Nm3/hr)

Slit Quantity: 10 x 5mm Ø holes

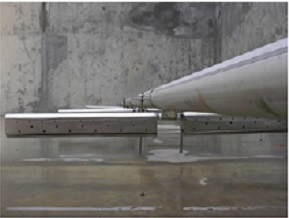

WIDE BAND DIFFUSERS

Ideal for aerobic digesters, channels, equalization tanks and grit chambers

- SSI Wide Band diffusers are available in 304L or 316L stainless steel

- Designed to be clog-free with oxygen transfer rates of 0.5 to 0.8% per foot of submergence (1.7 to 2.5% SOTE/m)

- Reliable alpha value plus economic design to cover tank floor make the SSI Wide Band the ideal choice for mixing in aerobic digesters, channels, equalization tanks and grit chambers

- Cast endcaps are welded all around

- Removable deflectors supplied with each diffuser

Easy install upgrade for a plugged diffuser

- Simply unscrew your Wide Band type diffuser from the existing piping system, and replace it with an SSI Aeration fixture

- Reduce worrying about clogging or turndown

- Save money, time and aggravation for minimal expense

Design Flow: 10-40 SCFM (17-67 Nm3/hr)

Flow Range: 0-4- SCFM (0-67 Nm3/hr

Hole Quantity: 44

Length: 24” (600mm)

FINE BUBBLE TUBE DIFFUSER

SSI Aeration’s Tube Diffuser and advanced membrane materials offer outstanding resistance to chemicals and fouling, in addition to the highest oxygen transfer with an acceptable headloss

QUALITY MAKES SSI’S TUBE DIFFUSER THE BEST CHOICE FOR RETRIEVABLE GRIDS

- Industry standard size and shape, interchangeable with other systems

- Connector options: standard nipple pipe connection or SSI’s Snappy Saddle™ Mount which makes one-person installation easy

- Variety of lengths, diameters and membranes in 21st century materials

- Excellent fouling resistance thanks to PTFE-coated surface layers, fEPDM™, anti-static EPDM

- Multiple integral check vales to keep your aeration piping system clean

- Molded membranes with individual thermocouples in each cavity provide 100% quality control

- Low membrane plasticizer content to reduce shrinkage and hardening, but enough to avoid creep

- 212F (100C) temperature resistance and environmentally friendly high temperature ABS body

- Affordably priced for first use or retrofit

ECD DIFFUSERS

For cost conscious customers SSI Aeration offers our economy line of diffusers. The ECD diffusers (Patent Pending) are composed of a single piece molded body integrated with SSI’s standard EPDM membrane. The single mold body allows SSI to offer a lower price point per diffuser while still including our proven EPDM membranes. The single mold design does not allow for membrane replacement, however given its low initial cost the entire diffuser is easily replaceable.

Available in both 7″ and 9″ diameter the ECD diffuser series features a 3/4 MNPT connection and is compatible with our PVC Grommet.

- Available in both 9″ and 7″ diameter sizing

- Single mold design allowing cost savings

- Standard EPDM membrane injected into Diffuser

- Popular in applications where capital cost is a deciding factor